Marvelous Info About What Is The Purpose Of A Torque Sensor

Torque Sensor How They Work And Their Applications

Decoding the Mystery

1. Understanding Torque

Ever wondered how engineers make sure things don't just... snap? Well, a big part of that is understanding torque. Think of it as the twisting force that makes things rotate. You use torque every time you turn a doorknob, tighten a bolt, or even steer a car. It's the unseen muscle behind many of our daily actions, and measuring it accurately is more important than you might think.

Now, imagine trying to build a precise engine or a reliable robot arm without knowing exactly how much twisting force is being applied at different points. That's where our handy friend, the torque sensor, comes in. This little device acts like a tiny detective, constantly monitoring and reporting on the amount of torque in a system.

Without a torque sensor, you'd be flying blind, guessing at the forces involved and hoping for the best. And in engineering, hoping isn't really a strategy. Precision and control are paramount, especially when dealing with powerful machinery or delicate instruments.

So, in essence, the torque sensor provides crucial data that allows engineers to optimize designs, prevent failures, and ensure the overall safety and efficiency of countless applications. Its a vital component in making things work smoothly and reliably.

2. The Torque Sensor

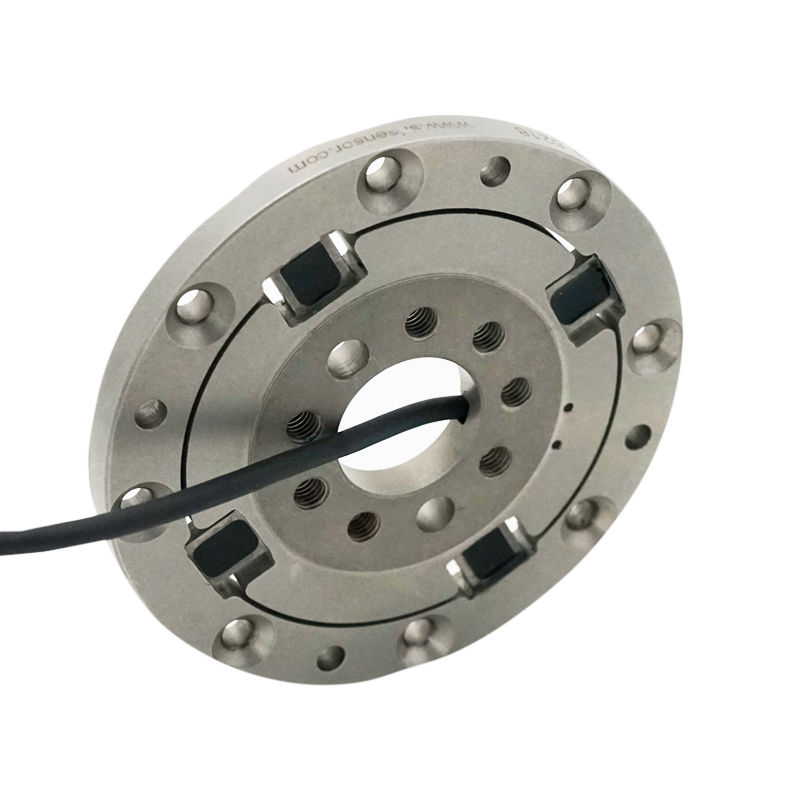

Let's dive a bit deeper. At its heart, a torque sensor is a transducer — a fancy word for something that converts one form of energy into another. In this case, it converts the twisting force (torque) into an electrical signal. This signal can then be measured, analyzed, and used to control various systems.

Think of it like this: you squeeze a stress ball. The harder you squeeze, the more resistance you feel. A torque sensor essentially measures that resistance to twisting, but instead of feeling it with your hand, it translates it into an electrical signal that a computer can understand. This is usually achieved through strain gauges, tiny resistors that change their electrical resistance when they are deformed (stretched or compressed) by the applied torque.

These changes in resistance are incredibly small, which means the sensor needs to be highly sensitive and accurate. That's why a lot of clever engineering goes into designing these devices to minimise noise and ensure reliable readings. You wouldn't want your torque sensor to mistakenly report a massive spike in torque when it's just a slight vibration, would you?

Different types of torque sensors exist, each with their own strengths and weaknesses. Some are designed for static torque (constant twisting force), while others are better suited for dynamic torque (torque that changes rapidly over time). The best choice depends on the specific application.

Torque Sensor Training Part 2 Different Types Of Sensors YouTube

Where Do We Find These Clever Devices?

3. Applications Across Industries

You'll find torque sensors in more places than you might imagine. They're the unsung heroes of numerous industries, ensuring precision and reliability in a wide range of applications. From automotive engineering to aerospace, and even in robotics, these sensors play a critical role.

In the automotive world, torque sensors are essential for testing engines, transmissions, and other components. They help engineers optimize engine performance, improve fuel efficiency, and ensure that everything is running smoothly. They're also becoming increasingly important in electric vehicles, where precise torque control is crucial for maximizing range and performance.

Aerospace relies heavily on torque sensors for testing aircraft engines, control surfaces, and landing gear. The extreme conditions in flight demand extremely reliable components, and accurate torque measurement is paramount for safety and performance. Imagine the consequences of a faulty torque reading during a critical maneuver!

Robotics also benefits enormously from torque sensors. They enable robots to perform delicate tasks with precision and control. Think of a robotic arm assembling intricate electronic components — a torque sensor helps it apply just the right amount of force to avoid damaging anything. Plus, they can even add safety features by detecting unexpected resistance, preventing damage or injuries.

4. Everyday Examples

While the applications mentioned above might seem a bit specialized, torque sensors are also present in many everyday devices. Consider power tools like electric drills and screwdrivers. Many modern models incorporate torque sensors to prevent over-tightening screws or damaging materials. It's that satisfying "click" you hear when you've reached the correct torque setting!

Even bicycle manufacturers use torque sensors when designing and testing components. They need to ensure that the frame, handlebars, and other parts can withstand the stresses of everyday riding and the occasional unexpected impact. A properly designed bike provides a safe and enjoyable experience. Improper torque can be... painful.

Furthermore, medical devices also rely on torque sensors to provide precise control and feedback. Think about surgical instruments, robotic surgery systems, and even prosthetics. In these sensitive applications, accuracy and reliability are absolutely crucial.

Basically, anywhere you need to measure or control rotational force with any degree of precision, theres a good chance a torque sensor is involved, working diligently behind the scenes.

Why Are Torque Sensors So Important?

5. Boosting Efficiency and Preventing Catastrophes

Torque sensors are not just about measuring things; they're about boosting efficiency, preventing catastrophic failures, and ensuring overall system reliability. They give engineers the data they need to optimize designs, monitor performance, and detect potential problems before they become serious.

Imagine a wind turbine, constantly subjected to varying wind speeds and loads. A torque sensor on the turbine's gearbox can monitor the amount of stress on the gears and bearings, allowing operators to adjust the turbine's settings to maximize energy production while minimizing wear and tear. This prolongs the lifespan of the turbine and reduces the risk of costly repairs.

In manufacturing, torque sensors can be used to monitor the performance of automated assembly lines. By tracking the torque applied by each robot arm, engineers can identify potential bottlenecks or malfunctions and take corrective action before they lead to production delays or quality issues. Its like having a watchful eye on the entire process.

The information provided by torque sensors can also be used to improve safety in a variety of applications. For example, in the construction industry, torque sensors can be used to monitor the tension on bolts and cables, ensuring that structures are stable and secure. This can help prevent collapses or other accidents.

6. Improving Control and Accuracy

Beyond preventing disasters, torque sensors significantly improve the control and accuracy of many processes. In precision machining, for instance, torque sensors can be used to monitor the cutting force on a tool, allowing operators to adjust the cutting parameters to achieve the desired surface finish and dimensional accuracy.

In robotics, torque sensors enable robots to perform complex tasks with greater precision and dexterity. By providing feedback on the amount of force being applied, torque sensors allow robots to adapt to changing conditions and avoid damaging delicate objects. Think of a robot assembling a circuit board — the torque sensor ensures each component is placed with just the right amount of pressure.

Even in seemingly simple applications, torque sensors can make a big difference. Consider a bottling plant where caps are automatically tightened on bottles. A torque sensor can ensure that each cap is tightened to the correct level, preventing leaks and preserving product quality. A seemingly small adjustment, but it can save a lot of headaches (and spilled soda!).

In short, torque sensors are essential for achieving optimal control and accuracy in a wide range of applications, leading to improved efficiency, reduced waste, and higher quality products. They truly are the unsung heroes of modern engineering.

FAQ

7. Frequently Asked Questions

Let's tackle some common questions about these twist-detecting dynamos!

Q: What are the main types of torque sensors?A: Great question! You'll typically encounter strain gauge torque sensors (the most common), rotary variable differential transformer (RVDT) sensors, and surface acoustic wave (SAW) sensors. Each has its own pros and cons regarding accuracy, robustness, and cost. The best one depends on the application.

Q: How do I choose the right torque sensor for my application?A: Its all about matching the sensor's capabilities to your needs. Key factors include the torque range you need to measure, whether you're dealing with static or dynamic torque, the operating environment (temperature, humidity, etc.), and the required accuracy. Don't forget to consider the cost and ease of integration into your system.

Q: Can torque sensors be recalibrated?A: Absolutely! Like any precision instrument, torque sensors can drift over time. Regular calibration ensures they maintain their accuracy. The frequency of calibration depends on the sensor's usage and the criticality of the measurements. Its like tuning a guitar keep it in tune for the best performance!